Considering a 100 amp subpanel installation? Our guide simplifies the process for California homeowners, from planning and load calculation to wiring and costs.

Date

Dec 21, 2025

Author

RC Admin

Read

9 min

Adding a 100 amp subpanel is a fantastic way to boost your home's electrical muscle, giving you a dedicated power hub for a new workshop, an EV charger, or even a small guest house. It basically acts as a branch off your main electrical service, delivering plenty of power to high-demand areas without putting a strain on your primary system. This kind of upgrade is perfect when you're making a big addition that needs more juice than a couple of new circuits can handle.

Deciding If a 100 Amp Subpanel Is Right for You

Before diving into any electrical project, the first step is always to make sure a 100 amp subpanel is what you actually need. Think of it as a satellite electrical panel designed for a specific zone of your home. It’s the go-to solution for powering areas with multiple, high-draw appliances or tools, making sure they get a steady source of power without causing flickering lights elsewhere.

For many California homeowners, this capacity is the sweet spot. It provides robust power for most residential projects without being overkill. If you want a refresher on the basics, you can check out our detailed guide on what is a subpanel.

When a 100 Amp Subpanel Is a Good Fit

A 100 amp subpanel is a real workhorse, perfectly sized for projects that need a good amount of power but not an overwhelming supply. Homeowners often find it's just right for some of the most common upgrades.

The table below breaks down a few common projects to help you see if a 100 amp subpanel fits your plans.

Project or Added Load | Typical Power Requirement | Is a 100 Amp Subpanel a Good Fit? |

|---|---|---|

Garage Workshop | 30-60 amps (for multiple tools) | Yes. It can easily run a table saw, compressor, and welder. |

Level 2 EV Charger | 40-60 amps | Yes. Leaves plenty of room for other garage circuits. |

Accessory Dwelling Unit (ADU) | 60-100 amps (depending on size) | Yes, for smaller ADUs with a kitchenette and bathroom. |

Home Addition | 50-80 amps | Yes. Ideal for a new master suite with its own HVAC. |

Hot Tub or Pool | 50-60 amps | Yes. Provides dedicated, safe power for the equipment. |

As you can see, a 100 amp subpanel provides more than enough capacity for most modern home additions and high-demand appliances.

When to Think Bigger

While it's versatile, a 100 amp subpanel isn't limitless. If your plans are on the larger side, you might need a more powerful solution. For instance, building a large ADU with a full-size kitchen, multiple bathrooms, and central air could easily push you past the 100 amp limit.

Likewise, if you plan to power several high-demand systems at once—say, a workshop, an EV charger, and a hot tub all running off the same subpanel—you’re probably asking for trouble. In those cases, a larger subpanel or even a full main service upgrade would be the safer and more practical choice.

Key Takeaway: The goal here is to build an electrical system that's safe, efficient, and ready for whatever you throw at it next. That includes planning for future additions, like a dedicated circuit for a Generac home backup generator to keep the lights on during an outage.

This isn't just our opinion; the numbers back it up. In the global electrical subpanel market, units between 100–200 amps are projected to hold a 35.7% market share, making them the top choice for residential projects. This trend really underscores their perfect balance of power and practicality for today's homes.

If you're in California and think a subpanel installation is the right move, our team at RC Generators is here to help. Contact us today for a professional consultation to make sure your electrical upgrade is done safely and to code.

Planning Your Project and Navigating California Permits

A successful 100 amp subpanel installation starts long before you ever touch a wire. The real work begins with smart planning and a solid grasp of local requirements, especially here in California. If you rush this part, you're setting yourself up for expensive mistakes, failed inspections, and frustrating delays.

Your first big decision is figuring out the perfect spot for the new subpanel. This single choice affects everything from material costs and how complex the job will be to the overall safety of the installation. You’ll want a location that's easy to get to for maintenance or if you ever need to reset a breaker.

Also, think about how far it is from your main electrical panel. A shorter wire run is always better. It saves money on materials and, more importantly, reduces voltage drop that can sap power from your tools and appliances.

Choosing the Best Subpanel Location

Finding the right home for your subpanel is a balancing act between convenience and code compliance. Both national and local electrical codes have strict rules about where panels can and cannot go.

Here are a few key things to keep in mind:

Dry and Accessible: The subpanel has to be in a dry, indoor spot. That means no damp basements, bathrooms, or any area prone to moisture. It also needs a dedicated clear space in front of it—usually 30 inches wide and 36 inches deep—so nothing ever blocks it.

Proximity to Loads: It makes sense to put the subpanel closer to the area it will serve, like your workshop or garage. This simplifies the wiring for each new circuit and is much more efficient than running a dozen long wires all the way back to the main panel.

Distance from Main Panel: While you want it near the new equipment, you also need to keep the heavy feeder wire from the main panel as short as practical. This thick-gauge wire is expensive, and longer runs might force you to buy an even thicker, pricier wire just to avoid power loss.

A classic example is installing a subpanel in a garage for a new EV charger and some workshop tools. By placing it on the wall closest to the main panel, you could save hundreds on wiring costs while still having it perfectly positioned for the new circuits.

Decoding the California Permitting Process

In California, putting in a new subpanel isn’t just a weekend project—it’s a major electrical upgrade that absolutely requires a permit. Trying to skip this step is a huge mistake. It can void your homeowner's insurance and create massive headaches if you ever decide to sell your home.

The permitting process is there to make sure the work is done safely and gets inspected by a qualified professional. Your local building department should be your first call. A quick chat or a visit to their website will get you the exact forms and requirements for your city or county.

Navigating the permit process is a non-negotiable part of a safe and compliant 100 amp subpanel installation. It’s the system's way of verifying that the work meets stringent safety standards designed to protect your home and family.

Typically, you'll need to submit a basic electrical plan. Don't worry, this doesn't have to be some fancy architectural drawing. It often just needs to show the location of the main panel, the proposed subpanel, the path for the feeder wire, and a list of the new circuits you're adding.

When applying for permits for your subpanel installation, especially if it involves new construction or significant changes to your property's layout, you will often need to provide a detailed site plan. For homeowners unfamiliar with this, you can learn more by understanding site plan requirements to ensure your application is complete.

Proper planning and permitting are the foundation of a successful project. If you’re getting your home ready for a powerful Generac generator or another big upgrade, getting this step right is crucial. For California homeowners who want total peace of mind, contact RC Generators and Electric today, and let our licensed pros handle the entire process for you.

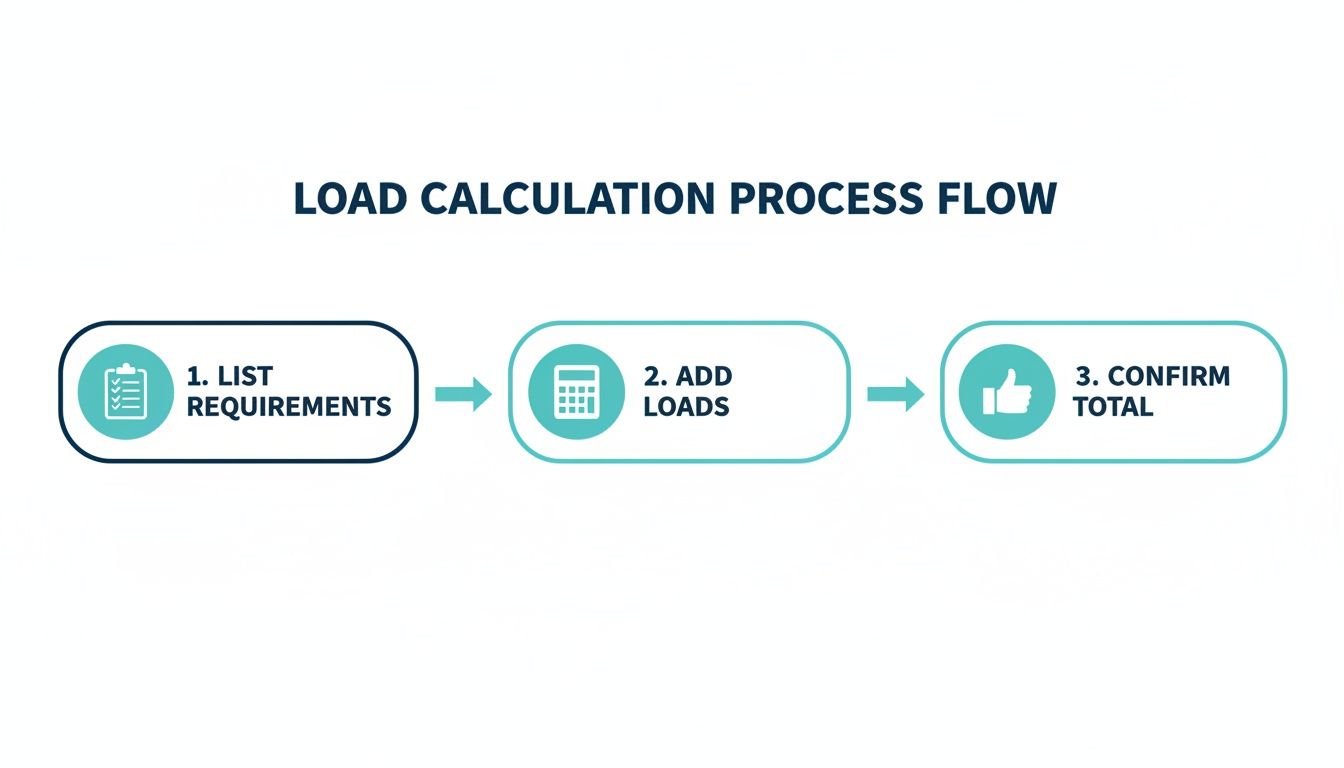

Calculating Your Electrical Load to Prevent Overloads

Guessing your home's power needs is a surefire way to end up with constantly tripped breakers or, worse, an unsafe electrical setup. Before you even think about installing a 100 amp subpanel, you have to nail down the total electrical load it will be expected to handle. Honestly, this is the most critical step for making sure your system runs safely and reliably for years.

The whole process is a lot simpler than it sounds. You just need to create a detailed list of every single thing that will draw power from that new subpanel. And I mean everything—not just the big-ticket items.

Cataloging Your Power Demands

Start by walking through the space, whether it's a garage, a new workshop, or a home addition. Make a list of everything that will be plugged in or hardwired. Don't leave anything out.

Your list should include things like:

Lighting: Every single overhead fixture, track light, and shop light.

Outlets: All the standard 120V outlets for general use. The National Electrical Code (NEC) has specific guidelines for calculating these loads.

Dedicated Appliances: This covers the heavy hitters like a refrigerator, a deep freezer, or a dedicated space heater.

High-Demand Equipment: This is where you list your workshop toys—the table saw, air compressor, welder, or maybe a Level 2 EV charger.

Once you have your list, you need to find the power rating for each item. It's usually on a sticker or plate right on the device, listed in either watts (W) or amps (A).

A Real-World Workshop Example

Let’s make this practical. Say you're finally building that dream workshop in your garage and need a 100 amp subpanel installation to power it all.

Your equipment list might look something like this:

240V Air Compressor: 20 amps

240V Welder: 50 amps

Level 2 EV Charger: 40 amps

General Lighting and Outlets: Calculated at around 15 amps

Now, it's tempting to just add those up (20 + 50 + 40 + 15), but that’s not how it works. The NEC knows you won't be running everything at full blast at the same time, so there are specific rules for these calculations. For a deeper dive into how it's done right, check out our guide on how to calculate electrical load for your home.

This is exactly why a proper load calculation is so important—it keeps you from overloading the subpanel, which is a major fire hazard. A correctly sized panel ensures you have enough capacity for everything you need now, plus a safe buffer for whatever you might add down the road.

The rise in home electrification is a huge reason why accurate load calculations are more critical than ever. With more high-draw appliances and EV chargers in homes, existing electrical systems are being pushed to their limits. A subpanel provides the necessary expansion, but only if it's sized correctly.

This trend is backed up by national housing data. A survey of U.S. single-family homes found that 29.5% still rely on main panels of 100 amps or less, which is driving the demand for subpanel upgrades. For homes under 1,000 square feet, that number jumps to a staggering 59%, showing just how many households are running out of electrical capacity for modern life. You can dig into the findings on electrical panel capacities yourself.

The bottom line is this: a 100 amp subpanel provides a ton of power, but it's not infinite. By taking the time to calculate your anticipated load, you're making sure your new setup will be a safe, reliable, and powerful asset. This is especially true if you plan to install a Generac home backup generator, which requires careful integration into your home's electrical system.

If you're in California and feel even a little unsure about doing these calculations, please don't guess. Contact RC Generators and Electric today for a professional assessment to guarantee your home's electrical system is perfectly balanced and ready for anything.

A Practical Walkthrough of the Installation Process

Okay, you've done the homework—the planning, permitting, and load calculations are all sorted. Now it’s time to roll up your sleeves for the hands-on part of a 100 amp subpanel installation. This is where precision and an absolute focus on safety are non-negotiable.

Before you touch a single wire, your first and most critical move is to kill the power. Head to your main electrical panel and shut off the main breaker to de-energize the entire system. Don't just trust the switch; use a voltage tester to confirm there's zero power flowing.

Once you're 100% certain the power is off, you can get to work. Start by securely mounting the new subpanel box to a wall stud in the location you picked out. Make sure it's perfectly plumb and level—this isn't just for looks. A crooked box means the breakers won't sit right and the cover won't fit flush.

Running the Feeder Wire

Next up is what's often the most physically demanding part: running the feeder wire from the main panel over to your new subpanel. This is a heavy-duty cable with four wires inside: two hot conductors, one neutral, and one ground. You'll need to figure out the best route, whether that's fishing it through an attic, a crawlspace, or running it inside conduit along a wall.

Getting the wire gauge right is crucial here. While the electrical code gives you a starting point, the sheer length of the wire run can cause voltage drop. You can dive deeper into this critical detail in our article on what size wire for 100 amp subpanel installations. Choosing the right size ensures everything you plug in gets the full power it needs to run properly.

The demand for these upgrades is huge. The global market has seen over 420 million electrical panel installations, and 100-200A units now make up 35.7% of that market. They're the perfect size for handling modern additions like solar-powered generators or EV chargers.

This is a good time to double-check the load math you did earlier.

Following this simple process ensures your new subpanel has plenty of capacity for the circuits it will be powering.

Making the Right Connections

Connecting the wires is where your attention to detail really counts. When you open up the subpanel, you'll see several metal strips called bus bars. This is where you'll land your wires, and it's also where one of the most important rules of subpanel wiring comes into play.

Crucial Safety Rule: In a subpanel, you must keep the neutral and ground wires completely separate. The neutral bus bar must be isolated (floating) from the panel's metal case, while the ground bar gets bonded directly to it.

This separation is a vital safety measure. It makes sure the ground wire only carries current during a fault, preventing the metal housing of your tools and appliances from becoming dangerously energized. Most subpanels ship with a green bonding screw that connects the neutral bar to the case—your job is to find it and remove it.

With the grounds and neutrals separated and connected to their proper bus bars, you can then connect the two hot feeder wires to the subpanel's main lugs. Every single connection needs to be tightened down to the manufacturer's specified torque setting to prevent loose wires and dangerous overheating.

Installing New Circuit Breakers

With the main feeder wires connected, you can start snapping in the new circuit breakers for the individual circuits you'll be running. A good grasp of miniature circuit breaker technology is key to protecting each circuit properly.

Each breaker clips firmly onto the hot bus bars inside the panel. Once a breaker is in place, you’ll connect the "hot" wire for its circuit to the terminal screw on the breaker itself. The matching neutral and ground wires for that same circuit get connected to their respective bus bars.

Following this methodical process ensures every new circuit is correctly wired and protected. For many homeowners in California, adding a subpanel is also a key step in preparing for a Generac backup generator. It creates a dedicated, safe place to connect this essential power source.

If any of this sounds the least bit intimidating, that’s your cue to call a professional. For a safe, code-compliant 100 amp subpanel installation in the Los Angeles or Ventura County area, contact RC Generators and Electric for a free consultation today.

Common Mistakes and Knowing When to Call an Electrician

Thinking about tackling a 100 amp subpanel installation yourself is tempting, I get it. But with electrical work, there is zero room for error. A small mistake isn’t just about failing an inspection—it can create a ticking time bomb inside your walls, putting your home and family at serious risk.

Even DIYers who've done plenty of projects can get tripped up. I've seen some frequent and dangerous mistakes out in the field, like using the wrong wire gauge for the amperage, not tightening connections down enough, or mixing up the neutral and ground wires. Each of these slip-ups has consequences that aren't always obvious right away.

An undersized wire, for example, is a hidden fire hazard just waiting to overheat. Loose connections create tiny electrical arcs that can eventually spark a fire. But the most common error I see is improperly bonding the neutral and ground, which can turn the metal casings of your appliances live, creating a major shock hazard.

Recognizing Your Limits and When to Call a Pro

The most important tool in any DIYer's bag is the ability to know when to put the tools down and pick up the phone. Installing a subpanel is a massive leap from changing an outlet. The stakes are just plain higher.

So, how do you know you're in over your head? Here are a few dead giveaways that it's time to call a licensed electrician:

Your Main Panel is Old or Cramped: If your main panel is already stuffed with breakers or still has old-school fuses, adding a subpanel is a much trickier operation.

The Wire Run is Long or Complicated: Fishing heavy-gauge feeder cable through finished walls, attics, or underground conduit is a real art. It takes special tools and a deep knowledge of code requirements.

You're Guessing on Load Calculations: If you have any doubt whatsoever about how much power your new circuits will pull, don't guess. An electrician can run a precise calculation to make sure your system is safe and balanced.

You're Adding a Backup Power System: If this subpanel is part of a bigger project, like setting up a Generac home backup generator, professional installation is non-negotiable to ensure everything works together safely.

Hiring a professional electrician isn't just paying for labor; you're buying peace of mind. Their license and insurance protect you, and their experience guarantees the job is done right the first time, meeting all California electrical codes.

Deciding whether to DIY or call in a pro can be tough. This chart breaks down the common tasks to help you make a smart, safe choice.

DIY vs Professional Electrician for Your Subpanel

Task | Consider DIY If... | Hire a Pro When... |

|---|---|---|

Mounting the Panel Box | You're comfortable locating studs and can get the box perfectly level and secure on a simple wood surface. | The mounting surface is concrete, brick, or anything else that requires specialized tools and anchors. |

Running New Wires | The wire run is short, direct, and in an accessible area like an unfinished garage or basement. | The wiring has to snake through finished walls, across multiple floors, or be buried in underground conduit. |

Making Connections | You own a calibrated torque wrench and know exactly why separating neutrals and grounds is so critical. | You're unfamiliar with torque specs or the specific—and often crowded—layout of your main panel. |

Permits & Inspection | You have firsthand experience with your local building department and understand what inspectors are looking for. | You want to guarantee a smooth process and a passing grade on the first inspection without any headaches. |

Ultimately, the choice comes down to your experience and comfort level.

For homeowners in California, especially in Los Angeles and Ventura County, navigating these jobs is what we do all day, every day. When you're ready for a safe, code-compliant 100 amp subpanel installation, don't roll the dice. Contact RC Generators and Electric today for a free, no-obligation consultation.

Common Questions About 100 Amp Subpanel Installations

Adding a 100 amp subpanel is a big job, and it’s smart to have questions. Getting straightforward answers is the best way to feel confident about the project. Let’s walk through some of the most common things California homeowners ask when they’re planning this kind of electrical work.

From what it costs to why certain wires can't touch, knowing the details helps you make safer, better decisions.

How Much Does a 100 Amp Subpanel Installation Cost in California?

In California, a professional 100 amp subpanel installation usually runs between $1,200 and $2,800. That said, the final price really boils down to the specifics of your home and the job itself.

Here’s what moves the needle on cost:

Distance from the Main Panel: The further the subpanel is from your main service panel, the more that heavy feeder wire costs. A subpanel in an attached garage will be on the lower end, while one in a detached workshop 100 feet away will naturally cost more in both materials and labor.

Job Complexity: It's one thing to run a wire along an unfinished basement wall. It's another thing entirely to fish it through finished drywall, navigate a cramped attic, or bury conduit underground. The tougher the access, the more labor is involved.

Condition of Your Existing Panel: Sometimes, your main electrical panel needs a little work before it can safely support a new 100-amp breaker. If modifications are needed, that will add to the total.

Always get a detailed, itemized quote from a licensed electrician. You want to see everything broken down—materials, labor, and permit fees—so there are no surprises.

Do I Need a Permit to Install a Subpanel in My Home?

Yes, you absolutely do. In California, adding a subpanel is considered a major electrical upgrade, and your local building department will almost certainly require a permit. Don't even think about skipping this step.

Working without a permit can open you up to a world of hurt. We're talking fines from the city, your homeowner's insurance refusing to cover a claim if something goes wrong, and massive headaches when it’s time to sell your house. The permit ensures a qualified inspector signs off on the work, verifying it meets all current electrical codes. It’s a crucial safety check that protects you and your property.

What Size Wire Do I Need for a 100 Amp Subpanel?

The rule of thumb for a 100-amp subpanel is #3 AWG copper wire or #1 AWG aluminum wire. That covers the two "hot" conductors and the neutral. The separate ground wire is usually a bit smaller, often #8 AWG copper.

But hold on—it’s not just about the amperage. The length of the wire run is a huge factor. Electricity loses a bit of power (called "voltage drop") over long distances. To make up for that loss, you might need to "upsize" to a thicker gauge wire. This ensures your tools and equipment get the full, stable power they need to run safely and efficiently.

A good electrician doesn't guess. They'll run a proper voltage drop calculation to determine the exact wire gauge your specific setup requires.

Why Do Neutral and Ground Wires Have to Be Kept Separate in a Subpanel?

This is probably one of the most critical safety rules for a 100 amp subpanel installation, and it's a common point of confusion. In your main electrical panel, the neutral and ground wires are connected together, or "bonded." But in a subpanel, they must always be kept separate.

Keeping them separate gives the ground wire one single job: to be a dedicated safety path for electricity to escape to the earth if there's a short circuit. If you bond the neutral and ground together in the subpanel, the ground wire can start carrying current during normal operation. This is incredibly dangerous. It could energize the metal casing of your appliances, power tools, or even the subpanel box itself, creating a serious shock hazard.

Most subpanels ship with a green bonding screw or a metal strap designed to connect the neutral bar to the panel’s metal case. When installing a subpanel, that screw must be removed. This lets the neutral bar "float" independently from the grounded enclosure, which is exactly what you want for a safe system.

A safe and reliable electrical system is the backbone of any modern home, especially when you're planning for outages with a Generac home backup generator. If you’re in Los Angeles or Ventura County and want your subpanel project handled by the pros, RC Generators and Electric is ready to help.

Contact us today for a professional consultation and a free estimate!